-

English

-

Japanese

-

Korean

Managing inventory and operations effectively during peak and off-peak seasons is key to maintaining healthy cash flow, especially for businesses that experience significant seasonal demand. Failing to align your inventory with the rhythm of your business cycle can lead to either stockouts or overstocking, both of which can hurt your cash flow and profits. In this article, we’ll explore strategies to help you optimize inventory and operations, ensuring you’re well-prepared for seasonal cash flow changes.

Understand Seasonal Demand Patterns

The first step to optimizing inventory and operations is understanding your seasonal demand patterns.

Every business, whether retail, e-commerce, or service-oriented, experiences seasonal fluctuations. For example, a clothing brand might see higher demand for winter coats in the fall and winter, while an outdoor furniture company might peak in the spring and summer. Understanding these patterns allows you to plan your inventory, staffing, and operations accordingly.

Use Historical Data: Review past sales data to identify trends and pinpoint seasonal demand spikes.

Market Trends and Forecasting: Stay updated on industry trends and forecast demand by considering factors like holidays, special events, weather patterns, and market shifts.

Sales Seasonality: Categorize your products by how they perform during different seasons. Certain items might have consistent sales throughout the year, while others are highly seasonal.

Balance Inventory with Demand

Having too much inventory during a slow season can lead to excess stock that ties up cash flow, while not having enough inventory during peak seasons can result in lost sales opportunities. The key to balancing your inventory is having a flexible strategy that adjusts to demand fluctuations.

Use Just-in-Time (JIT) Inventory: JIT allows businesses to only order inventory when it’s needed, reducing the risk of overstocking and ensuring inventory turnover is high. This can be particularly useful in balancing seasonal cash flow.

Set Min/Max Stock Levels: Establish minimum and maximum inventory levels for each product based on forecasted demand. This way, you’ll always know when to restock and avoid over-purchasing.

Safety Stock: Keep a buffer of safety stock during peak seasons to prevent stockouts but be careful not to overstock, as excess inventory can eat into your working capital.

Plan Your Cash Flow Around Seasonality

Since your business may generate more revenue in certain months than others, it's essential to plan your cash flow to handle leaner times effectively. This means knowing when you’ll have more working capital to invest in inventory and when you need to tighten your budget.

Align Purchases with Expected Cash Flow: Don’t buy more inventory than you can afford just because you’re anticipating a busy season. Balance your purchasing with expected cash inflows, allowing enough liquidity for operational expenses.

Use Financing Options: Consider using short-term financing or lines of credit to cover cash flow gaps during low seasons. Be sure to plan repayment during high-demand months when cash flow is stronger.

Monitor Payment Terms: Negotiate better payment terms with suppliers during peak seasons to ensure you have the cash flow flexibility to pay for larger inventory orders. Longer terms allow you to sell inventory before paying suppliers.

Streamlining Operations for Efficiency

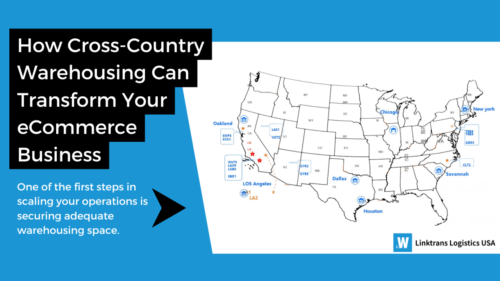

From warehousing to shipping, optimizing your operations helps reduce costs, improve service levels, and increase profitability, especially during peak seasons. Planning ahead ensures you’re not caught off-guard during busy times and helps minimize bottlenecks during slower periods. Automating processes through inventory management software can track stock levels in real-time, reducing human error and ensuring that inventory is always available in line with demand. During high-demand periods, outsourcing warehousing, fulfillment, or customer support tasks can help you scale operations without committing to permanent increases in staff. Temporary workers or utilizing third-party logistics (3PL) services offer a flexible, cost-effective solution. Additionally, offering multiple shipping choices, like expedited shipping during peak seasons or optimized packaging during off-peak periods, can improve your service and help manage operational costs.

Monitoring Inventory Turnover and Adjusting

Once your inventory strategy is in place, constant monitoring is essential. Market conditions can change, and your demand may shift unpredictably. Regularly monitoring inventory turnover and sales performance ensures that you’re staying on top of your operational and financial goals. Tracking inventory turnover allows you to see how quickly stock is moving and when to reorder, ensuring that you maintain a healthy inventory level without overstocking. Reviewing your forecasts and adjusting them based on real-time data allows you to fine-tune your buying strategy, ensuring your purchasing decisions align with actual demand. Post-season clearance events, such as offering promotions or discounts, are excellent ways to move slow-moving products and free up cash flow for the next cycle. By staying agile, you can quickly react to changing market conditions and keep your inventory strategy on track.

Building Strong Supplier Relationships

Strong relationships with suppliers help you manage inventory effectively, especially during high-demand periods. The ability to place quick orders or get priority shipments can make a significant difference in meeting customer demand while maintaining your cash flow. Negotiating favorable terms with suppliers, such as extended payment options or priority fulfillment during peak seasons, ensures you’re well-prepared for the busiest times of the year. It’s also beneficial to diversify your suppliers to reduce the risk of delays or stockouts during spikes in demand. By sharing sales data and forecasts with your suppliers, you can align production schedules with your seasonal needs, ensuring that they can ramp up production when necessary and avoid costly delays. This collaborative approach allows for smoother operations and ensures you’re always ready to fulfill orders on time.

Use Seasonal Promotions to Drive Sales

Running targeted campaigns during peak times helps clear out old inventory, make room for new stock, and increase your overall cash flow. Be sure to align your promotional efforts with your seasonal demand to maximize impact.

Bundle Products: Offering product bundles or gift sets can encourage customers to buy more, helping you move excess stock during the off-season.

Run Flash Sales: Flash sales during high-demand periods can help you capitalize on customer interest, boost cash flow, and reduce excess inventory.

Early Bird Discounts: For products that are relevant during specific seasons, offering early discounts can generate cash flow before peak season, enabling you to purchase more stock and scale operations.

Final Thoughts

Successfully optimizing inventory and operations to match seasonal cash flows requires a balance of strategic planning, monitoring, and flexibility. By aligning your inventory management and operational tactics with demand fluctuations, you can maintain healthy cash flow, reduce operational costs, and ultimately grow your business. Seasonality is a part of every business cycle, and with the right approach, you can use it as an opportunity to maximize profits and ensure your company thrives all year round.