-

English

-

Japanese

-

Korean

What’s the one thing that eats up your time as a business owner? For many, it’s keeping track of inventory. Let’s face it—counting stock, updating records, and figuring out what’s missing can feel like a never-ending chore. But what if there was a better way? Imagine a system that does the work for you, updating your inventory every time you make a sale, receive new stock, or even spot an issue. Sounds like a dream, right? The good news is, this system exists, and it’s called a Perpetual Inventory System.

Let’s dive in and see how it stacks up against traditional methods.

What is Perpetual Inventory System

A Perpetual Inventory System is an inventory management method that continuously tracks inventory levels in real time. Unlike a periodic inventory system, which updates inventory data at specific intervals (e.g., monthly or annually), a perpetual inventory system records changes in inventory as they occur. This system uses technology, such as barcodes, RFID (radio-frequency identification), or point-of-sale (POS) systems, to automatically update inventory records whenever items are purchased, sold, returned, or moved.

Example of a Perpetual Inventory System

A large supermarket chain, such as Walmart, uses a perpetual inventory system to manage its vast inventory across multiple locations. Here’s how it works in practice:

Point-of-Sale (POS) System Integration:

Every item in the supermarket is tagged with a barcode. Whenever a customer purchases an item, the cashier scans the barcode using a POS system. The system automatically updates the inventory database in real time, deducting the quantity of the sold item from the available stock.

- Example: A customer buys 2 cartons of milk. The POS system immediately records the sale and reduces the milk inventory by 2 cartons in the database.

Real-Time Stock Monitoring:

The supermarket’s inventory management software continuously tracks the stock levels of all items. If the stock of an item falls below a predetermined threshold (reorder point), the system generates an alert or automatically places an order with the supplier to replenish the stock.

- Example: If the inventory of milk drops to 10 cartons (the reorder point), the system sends an automatic order to the supplier to deliver more milk.

Receiving New Inventory:

When new inventory arrives, the system updates stock levels as soon as the items are scanned and entered into the system. This ensures that the inventory records are always up-to-date.

- Example: A delivery of 50 cartons of milk is received at the supermarket. The staff scans the cartons, and the system adds 50 cartons to the current inventory count.

Shrinkage and Adjustments:

The system also allows for adjustments to account for inventory shrinkage due to theft, spoilage, or damage. These adjustments are logged in the system to maintain accurate records.

- Example: If 3 cartons of milk are found spoiled during a routine check, the system adjusts the inventory count and records the reason for the loss.

Reports and Analytics:

The perpetual inventory system generates detailed reports, such as sales trends, stock movement, and profit margins. This helps the supermarket make informed decisions about pricing, promotions, and inventory planning.

- Example: The system identifies that milk sales increase by 20% on weekends, prompting the supermarket to stock extra cartons before the weekend rush.

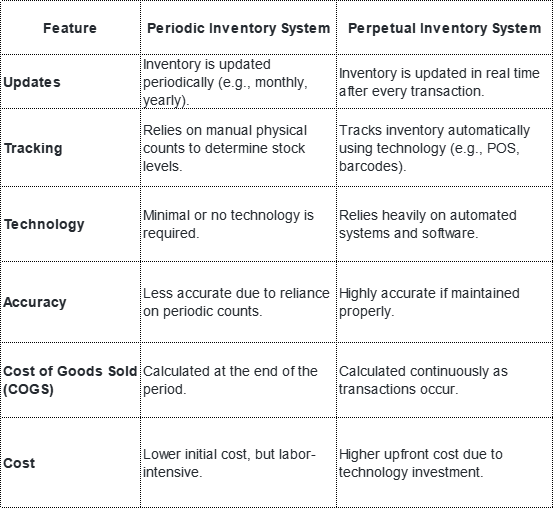

Periodic inventory system vs perpetual

The Periodic Inventory System and Perpetual Inventory System are two methods businesses use to track and manage inventory. Below is a detailed comparison of the two systems, highlighting their key differences, advantages, and disadvantages.

Periodic Inventory System:

Inventory is updated at specific intervals (e.g., monthly, quarterly, or annually). Changes in inventory levels are determined by conducting physical counts and calculating the cost of goods sold (COGS) at the end of the period.

Perpetual Inventory System:

Inventory is updated continuously in real-time as transactions occur. This system uses technology, such as barcodes and point-of-sale (POS) systems, to automatically track inventory movements.

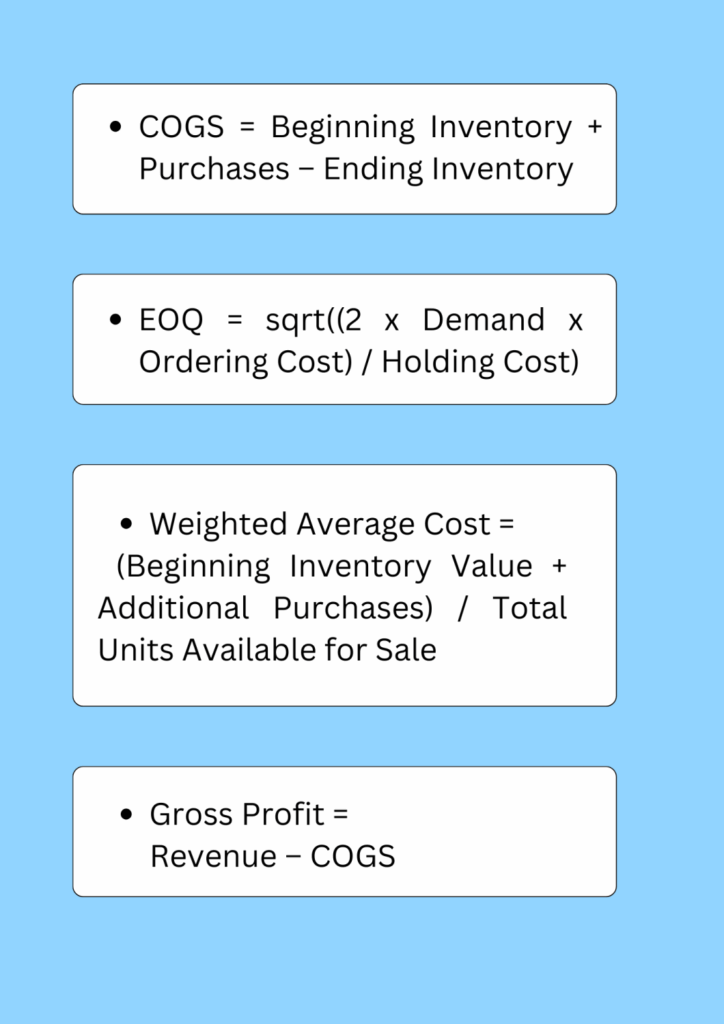

Perpetual Inventory System Formulas

The Perpetual Inventory System offers businesses a dynamic and accurate way to manage inventory in real time, ensuring they can respond quickly to changing demand, minimize stockouts, and reduce overstocking. While it requires a higher initial investment in technology and maintenance, the benefits of automation, improved accuracy, and actionable insights far outweigh the costs for businesses that need precise inventory control.