-

English

-

Japanese

-

Korean

When it comes to running a successful ecommerce business, logistics and fulfillment are often the unsung heroes. You might have the best products on the market, but if your delivery times are slow or shipping costs are too high, your customers won’t stick around for long. That’s where the location of your warehouse—specifically your fulfillment centers—becomes a game-changer. Let’s break down how choosing the right locations for your warehouse can improve speed, reduce costs, and enhance your service offering.

Why Fulfillment Center Locations Matter

Think about it: when you’re shopping online, the two main things you care about are how fast the product gets to you and how much it costs. If a customer’s order takes too long to arrive, they’ll likely shop elsewhere next time. If shipping is too expensive, they’ll think twice about making a purchase. Both of these outcomes directly impact your revenue.

Choosing the right warehouse location means you can fulfill orders faster and at a lower cost. When your fulfillment center is close to your customers, shipping times and expenses decrease, which improves customer satisfaction and loyalty. But it’s not just about proximity—it’s about choosing locations where the benefits extend beyond just shipping times.

The Best Location for Your Fulfillment Warehouse

If you want your goods to be delivered closer and faster to their destination and think that coastal warehousing and distribution locations are better, you are mistaken.

Coastal distribution centers are more likely to suffer from capacity constraints than inland distribution centers. These areas have limited physical space. This means that pricing in these distribution centers is based on scarcity and inflation, not value. Storing more inventory in such a congested area may cost too much.

Congestion also poses a risk. Even if you meet your delivery commitments, there may be a large number of touchpoints involved, as carriers may bypass areas that are more prone to bottlenecks. These additional handoffs or longer routes may add more cost than inland fulfillment services.

You can avoid these risks by shipping goods from the port to an inland distribution center away from the coast. Remember, distribution companies can work with you no matter where your office is located.

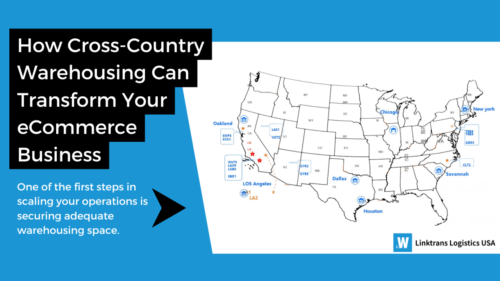

Finding 3PL Warehouse Space Near Customers

Working with a third-party logistics provider (3PL) gives you access to an extensive network of warehouses without the need to own or manage them yourself. With 3PLs, you can strategically choose locations near your customer base, allowing you to reduce transit times and shipping costs.

When looking for 3PL warehouse space, it’s important to choose providers with a wide range of distribution centers. Ideally, your 3PL should have multiple warehouses spread across major population centers or close to your biggest customer markets. The closer your inventory is to your customers, the faster and cheaper it will be to get it to them.

Local Fulfillment Centers and Delivery Time

Speed is everything in ecommerce. Customers expect fast delivery, often within 1-2 days. By having local fulfillment centers, you can drastically reduce delivery time. In fact, some businesses can even offer same-day or next-day delivery if their warehouses are located in strategic areas.

For instance, if you have a fulfillment center in the Midwest and another in the Southeast, a customer in Chicago will get their order much faster than if you had a single warehouse located in California. This kind of regional distribution ensures you're able to meet customer expectations without breaking the bank on shipping costs.

Benefits of Strategically Located 3PL Warehouse Space

When you strategically place 3PL warehouse locations, you're not just improving delivery times—you’re also reaping several other benefits.

Cost Reduction: By minimizing transit distances, you reduce fuel costs, handling fees, and other logistical expenses. This lowers your overall fulfillment costs and boosts your bottom line.

Improved Customer Service: Quicker delivery times translate to happier customers. Customers value reliability and speed, and by delivering on both fronts, you increase customer satisfaction, leading to higher retention rates and repeat business.

Flexibility: Strategic warehouse locations give you the ability to adjust quickly to shifts in demand. If a specific region sees a sudden uptick in sales, you can route inventory to that warehouse without affecting other areas of your business.

Scalability: As your business grows, the ability to scale your operations through multiple fulfillment centers becomes essential. A good location strategy means you can expand into new markets with minimal disruption to your supply chain.

Managing Inventory Across 3PL Locations

Managing inventory across multiple 3PL warehouse locations might sound complicated, but it doesn’t have to be. With the right tools and systems in place, you can streamline your operations and keep track of stock levels at each location.

Modern warehouse management systems (WMS) and inventory management tools help you monitor stock levels, forecast demand, and optimize fulfillment routes. By syncing all your locations in real time, you can ensure that you always have the right amount of stock in each warehouse and avoid overstocking or stockouts.

Key Takeaways for Your Warehouse Location Strategy

Proximity to Customers: The closer your fulfillment centers are to your customers, the faster and cheaper your delivery will be.

Strategic Distribution: Don't rely on a single warehouse. A distributed network of warehouses allows you to meet demand across different regions, improving delivery speed and reducing costs.

3PL Partnerships: Working with 3PL providers gives you access to a network of strategically located warehouses, so you don’t have to invest in your own facilities.

Inventory Management: Utilize modern technology to manage inventory across multiple locations and streamline your fulfillment processes.

Your Next Fulfillment Center Location

If you’re looking to grow your ecommerce business, the location of your next fulfillment center could be a key factor in your success. Whether you choose to open a new warehouse or partner with a 3PL provider, it’s important to think strategically about where you place it. The right location can help you meet your customer’s delivery expectations, reduce shipping costs, and improve your overall customer experience.

In conclusion, by choosing the right fulfillment warehouse locations, you’re positioning your business to deliver on time and at a cost that makes sense for your bottom line. After all, happy customers lead to repeat sales, and the quicker and more affordable you can get your products to them, the more likely they are to return.

Use linkW logistics USA to help with your warehouse transportation!

Expensive isn't always the best, choose a 3PL that meets your business needs with a local trucking team, clear routes, and a real-time tracking system to keep track of the progress of your shipments, all in one place.

Address:9570 Santa Anita Ave, Rancho Cucamonga, CA 91730

Address:14650 Meyer Canyon Dr, Fontana, CA 92336

Address:26318 Corporate Ave., Hayward, CA, 94545

Address:50 Jiffy Rd, Somerset, NJ 08873

Address:139 Prosperity Dr, Garden City, GA 31408