-

English

-

Japanese

-

Korean

Product returns are skyrocketing in ecommerce, impacting up to 40% of online purchases in some categories and contributing to the trillion-dollar global reverse-logistics market annually. An efficient warehouse returns process is critical to recovering value and maintaining customer satisfaction, covering every step from returns authorization, receiving inspection, sorting, quality control, replenishment, and responsibility assignment. Forward-thinking logistics providers, such as LinkW Logistics USA, complement these operations with modern warehouse management systems, automation, and flexible short-term and long-term pallet storage solutions to ensure returned goods are stored safely pending reintegration.

Receiving and Inspection

What happens when a return request comes in?

1.1 Return Authorization and Scheduling

The returns process begins even before the customer drops off the package: an effective warehouse returns process includes providing a pre-printed return shipping label with every outbound order or enabling customers to generate a return label online, reducing friction and ensuring that returns arrive quickly and in the correct facility.

1.2 Initial Inspection

Once a returned item arrives, warehouse staff or 3PL partners scan it into the warehouse management system, inspect for visible damage, verify the reason code, and confirm eligibility for resale or further processing. This initial check aligns with best practices for processing the return—including obtaining return authorization, scheduling return shipments, and reviewing proof of purchase before approving refunds or exchanges. Confirming resale eligibility before restocking helps prevent fraud and reduces downstream handling costs.

2. Sorting and Categorization

How do we decide where each returned item goes next?

Efficient warehousing requires sorting returned goods into disposition categories—repair, refurbishment, resale as new, open-box sale, recycling, or disposal—using clear criteria and reason codes to guide decision-making from the moment items are received. Early categorization minimizes handling time and ensures items follow the correct processing path, whether that means sending products to the repair department, returning them directly to inventory, or directing them to recycling streams.

3. Quality Control and Testing

How do we ensure returned products meet quality standards?

In dedicated quality-control stations, technicians perform functional and cosmetic inspections to verify that items operate correctly, meet safety requirements, and match original specifications. Products requiring more in-depth testing—such as electronics—may undergo performance benchmarking and component-level assessments to identify defects before determining whether they can be refurbished or must be scrapped.

4. Refurbishment or Repurposing

What happens when an item needs repair?

For items deemed repairable, our skilled technicians immediately begin refurbishment, which may include part replacement, cleaning, software updates, or reconditioning to restore products to like-new performance. By swiftly reintegrating repaired items back into inventory, we minimize downtime and recapture value that would otherwise be lost. When products cannot be fully restored, we disassemble them to harvest usable components, which are then forwarded to manufacturing partners, further supporting sustainable practices and reducing the need for new raw materials.

5. Restocking and Inventory Management

How do returned goods find their way back to your customers?

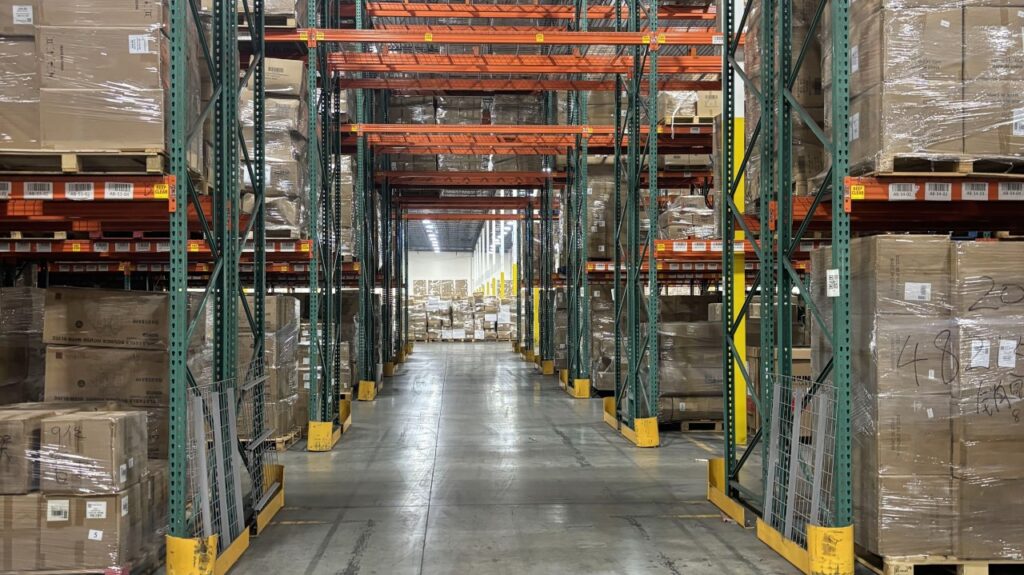

Once products pass quality control or refurbishment, they are relabeled—often as “open-box” or “refurbished with warranty”—and re-shelved in designated areas. Our warehouse management system updates real-time SKU counts, ensuring visibility across channels and preventing overselling. In cases where returned goods are undamaged, they may be restocked on regular shelves and made available for immediate pick-and-pack operations, optimizing inventory turns and maximizing shelf life.

6. Recycling and Disposal

How do we handle items that can’t be resold?

When products are beyond repair or refurbishment, we employ responsible disposal practices that prioritize recycling and minimize landfill waste. Wherever possible, items are disassembled, and materials such as plastics, metals, and electronics are separated and sent to certified recycling facilities. Non-recyclable components are safely discarded in compliance with environmental regulations, ensuring our reverse logistics processes support a circular economy and uphold our sustainability commitments.

7. Short-term and Long-term Storage Solutions

Where do returned goods go while they await processing?

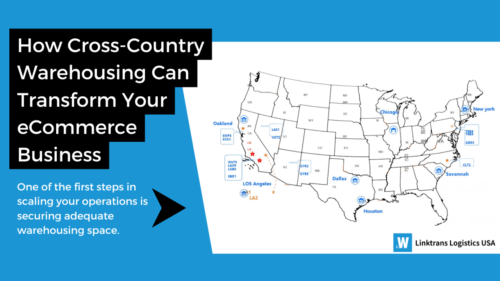

In many cases, returned goods may require short-term storage while awaiting inspection or longer-term storage during refurbishment and secondary sales planning. LinkW Logistics USA offers versatile pallet storage options—ranging from temporary holding areas for expedited processing to secure, climate-controlled long-term warehousing for seasonal returns or slow-moving items. Our pallet storage capacity is optimized to meet fluctuating return volumes, ensuring goods remain organized and accessible without compromising space efficiency.

8. Communication and Reporting

How do we keep stakeholders informed?

Transparent communication is key throughout the returns process. Our warehouse management system automatically generates status updates at each stage—receipt, inspection, repair, restock, or disposal—and can trigger customer notifications to enhance the post-purchase experience. Internally, we track KPIs such as return rate, average processing time, disposition yield, and recovery value to identify process bottlenecks and drive continuous improvement.

An effective warehouse returns process transforms the challenge of product returns into an opportunity for customer loyalty, cost recovery, and sustainability. At LinkW Logistics USA, our expertise in warehousing, reverse logistics, and pallet storage ensures your returned goods are handled with the care and professionalism your customers deserve.