-

English

-

Japanese

-

Korean

Managing inventory levels is a persistent challenge for online retailers, akin to an intricate juggling act. Keeping track of which SKUs are flying off the shelves and which items are gathering dust can be daunting. Just when you think you’ve nailed the right rhythm, inventory levels shift again. Consistently tracking inventory is crucial to optimizing logistics costs and meeting customer demand.

To avoid common inventory management pitfalls as your business grows, here’s what you need to know:

The significance of maintaining inventory levels

Real-time inventory tracking methods

How a fulfillment partner like LinkW logistics USA can assist in optimizing inventory to meet demand and cut costs

Understanding Inventory Levels

Inventory levels refer to the amount of stock available across a business’s fulfillment centers at any moment. Monitoring these levels helps brands maintain sufficient inventory to meet demand while avoiding overstocking.

Defining Optimal Inventory Levels

When e-commerce brands optimize their inventory levels, they can meet order demand, reduce common inventory problems, mitigate high storage costs, and minimize out-of-stock situations. Unbalanced inventory levels can lead to issues such as excess capital tied up in stock or stockouts that disappoint customers.

Why Maintaining Optimal Inventory Levels is Crucial

Having too much inventory can lead to overspending on storage and the risk of unsellable stock. Conversely, too little inventory can cause stockouts and backorders, reducing customer satisfaction. Understanding your stock levels helps in supply chain planning and improves inventory accuracy.

Determining Optimal Inventory Levels

Calculating optimal inventory levels involves analyzing historical order and inventory data, considering reorder timing, and factoring in production lead times, safety stock, and demand forecasting.

Best Practices for Maintaining Optimal Inventory Levels

Implement an Inventory Tracking System: Real-time access to stock levels across logistics centers and sales channels improves stock control.

Determine Reorder Points: Set reorder points to automate the reorder process based on customer demand and lead times.

Use an Inventory Management System: Sync SKUs and orders to view all inventory, fulfillment centers, sales channels, and customers in one place.

Communicate Clearly with Your Supplier: Clear communication with suppliers about expectations and schedules is essential.

Carry Out Inventory Audits: Regular inventory audits, automated and digitized, ensure accuracy and efficiency.

The Importance of Maintaining Inventory Levels

Maintaining optimal inventory levels is crucial for several reasons. Firstly, it helps ensure that you have enough stock to meet customer demand without overstocking. Overstocking can lead to high storage costs and the risk of unsellable stock. On the other hand, too little inventory can cause stockouts and backorders, which can hurt customer satisfaction.

Real-Time Inventory Tracking Methods

Real-time inventory tracking is essential for maintaining optimal inventory levels. There are several methods you can use to track inventory in real-time, including:

Inventory Management Software: Inventory management software can help you track inventory levels in real-time, set reorder points, and manage stock across multiple locations.

Barcode Scanning: Barcode scanning can help you track inventory levels in real-time by scanning items as they are received, stored, and shipped.

RFID Technology: RFID technology can help you track inventory levels in real-time by using radio waves to identify and track items.

How a Fulfillment Partner Like LinkW logistics USA Can Help

A fulfillment partner like LinkW logistics USA can help you optimize inventory to meet demand and save on costs. LinkW logistics USA offers several services that can help you manage inventory, including:

Inventory Management: LinkW logistics USA's inventory management system can help you track inventory levels in real-time, set reorder points, and manage stock across multiple locations.

Order Fulfillment: LinkW logistics USA can help you fulfill orders quickly and accurately, ensuring that you have enough stock to meet customer demand.

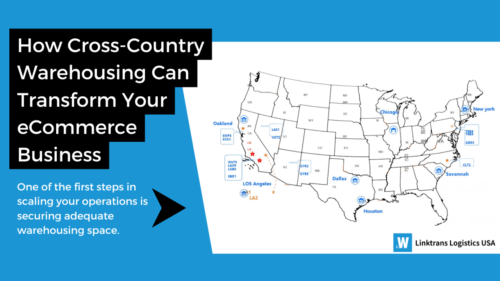

Warehouse Storage: LinkW logistics USA can help you store inventory in their warehouses, reducing the need for you to invest in your own storage facilities.

Maintaining optimal inventory levels is crucial for online retailers. By following best practices for inventory management, such as implementing an inventory tracking system, determining reorder points, using an inventory management system, communicating clearly with suppliers, and carrying out inventory audits, you can ensure that you have enough stock to meet customer demand without overstocking.